Views: 38 Author: Site Editor Publish Time: 2023-05-24 Origin: Site

Shade Net Making Machine: Creating Protective Covers with Efficiency

Shade nets are widely used in agriculture, horticulture, and other industries to provide protection from excessive sunlight, wind, and hail. These nets play a vital role in ensuring the healthy growth of crops and safeguarding plants from adverse weather conditions:shading,cooling,moisturizing. To meet the growing demand for shade nets, manufacturers rely on advanced technology and machinery, such as different kinds of shade net making machines. In this article, we will explore the world of shade net making machines, their benefits, working principles, types, factors to consider when choosing one, and maintenance tips.

Introduction

Shade net making machines are specialized equipment designed to manufacture shade nets in a highly efficient and automated manner. These machines use advanced techniques to produce shade nets with precise dimensions, uniform density, and superior strength. By automating the manufacturing process, shade net making machines enable high production capacity while maintaining consistent quality. Let's delve deeper into the advantages of using these machines.

Benefits of Using a Shade Net Making Machine

1.Improved Efficiency: Shade net making machines streamline the production process, allowing manufacturers to produce a large number of shade nets in a shorter time. This results in increased productivity and faster delivery times.

2.Consistent Quality: These machines ensure uniformity in the dimensions, density, and strength of the shade nets produced. This consistency in quality is crucial for meeting customer requirements and building a reputation for reliable products.

3.Customization Options: Shade net making machines can be configured to produce shade nets of various sizes, colors, and mesh patterns. This versatility allows manufacturers to cater to different customer preferences and market demands.

4.Reduced Labor Costs: Automating the manufacturing process reduces the need for manual labor, resulting in lower production costs and increased profitability. Additionally, it minimizes the chances of errors that may occur during manual production.

5.Durability and Longevity: Shade net making machines are built with robust materials and precision engineering, ensuring their durability and longevity. This longevity translates into long-term cost savings for manufacturers.

Types of Shade Net Making Machines

Monofilament Shade Net Making Machine

The monofilament shade net making machine is designed to produce shade nets using monofilament yarn. Monofilament yarn is HDPE material that offers excellent strength and durability. These machines with EBA let-off system are suitable for manufacturing high-quality shade nets used in agriculture, construction, and other industries.

Flat Yarn Shade Net Making Machine

The flat yarn shade net making machine produce shade nets using flat yarn which from flat extruder or blow film machine. Flat yarn is a type of synthetic material that is widely used for its lightweight nature and cost-effectiveness. It can use creel,slitter to let-off yarn.These machines are capable of producing shade nets used in various applications such as car parking shades, shade sail,vegetable flower awnings, and some balcony shade.

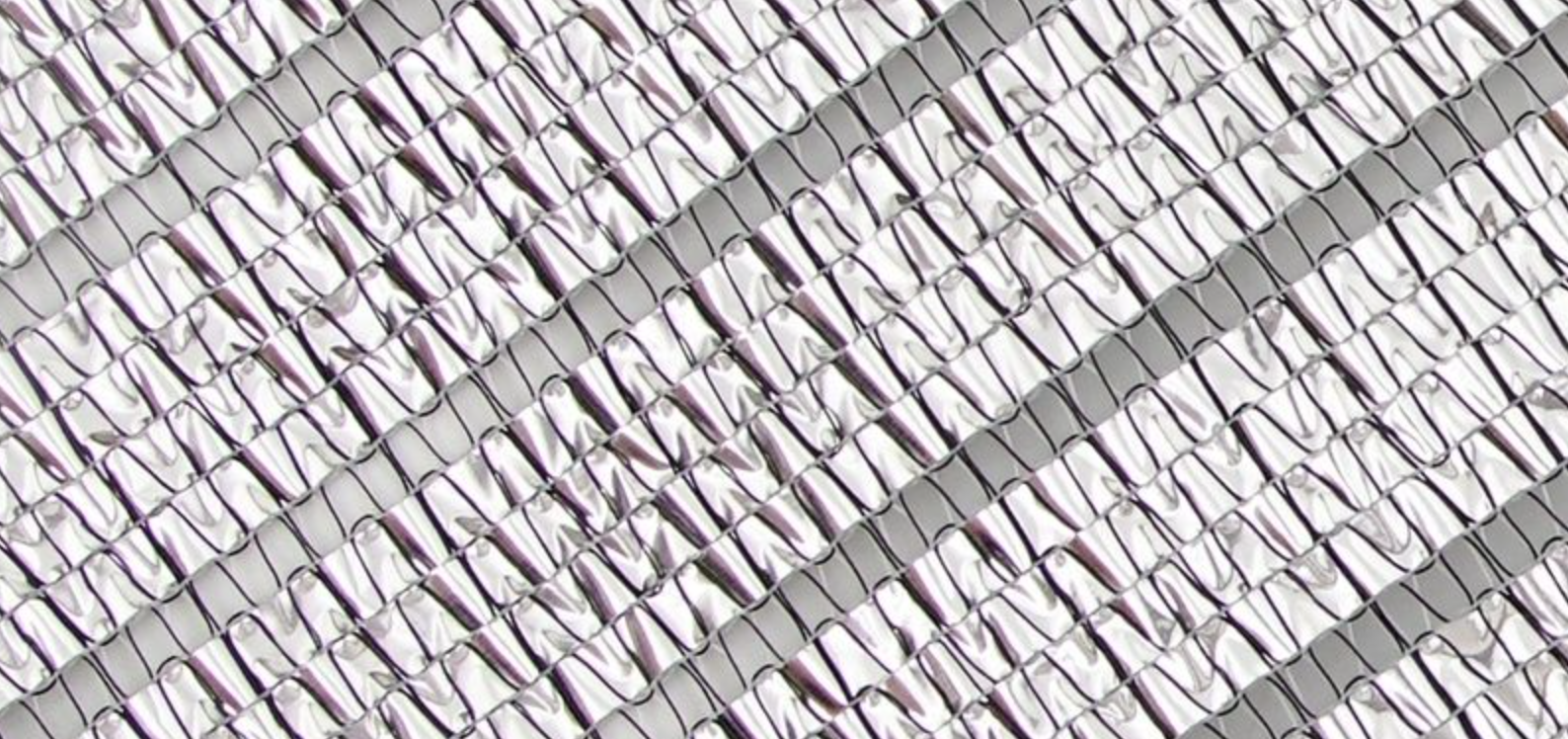

Aluminum Shade Net Making Machine

The aluminum shade net making machine is specifically designed to produce net using three kinds of material:aluminum flat yarn ,PET flat yarn,FDY yarn.This net is used for green house to plant precious flowers and trees,this net can prevent condensation,keep a stable temperature.

Factors to Consider When Choosing a Shade Net Making Machine

Production Capacity

When selecting a shade net making machine, it is crucial to consider the required production capacity. Manufacturers should assess their current and future demand to ensure the chosen machine can meet their output requirements.

Material Compatibility

Different shade net making machines are designed to work with specific materials such as monofilament yarn or flat yarn. Manufacturers should choose a machine that is compatible with the desired material to achieve optimal results.

Automation Features

Automation features, such as automatic yarn feeding, precise tension control, and computerized monitoring systems, can significantly enhance the efficiency and productivity of shade net making machines. It is essential to evaluate the available automation features and select a machine that aligns with specific production needs.

Cost and ROI Analysis

Investing in a shade net making machine is a significant decision for manufacturers. It is crucial to perform a thorough cost analysis, considering factors such as the machine's price, maintenance costs, energy consumption, and expected return on investment (ROI). A comprehensive evaluation will help make an informed investment decision.

Maintenance and Care Tips for Shade Net Making Machines

To ensure the longevity and optimal performance of shade net making machines, regular maintenance is necessary. Here are some maintenance and care tips:

·

Regular Cleaning: Using a air pressure to clean the machine after each production run to remove any accumulated dust or debris. This helps prevent clogging and maintains the machine's efficiency.

·

·

Lubrication: Apply lubricants to the machine's moving parts as recommended by the manufacturer. Proper lubrication reduces friction and extends the machine's lifespan.

·

·

Scheduled Inspections: Perform routine inspections to identify any signs of wear or damage. Timely repairs or replacements can prevent major breakdowns and production delays.

·

·

Operator Training: Train machine operators to follow the manufacturer's guidelines and best practices. Well-trained operators can identify minor issues and perform basic troubleshooting, ensuring smooth operations.

·

Conclusion

Shade net making machines revolutionize the production of shade nets, providing manufacturers with efficient, automated, and reliable manufacturing solutions. These machines offer numerous benefits, including improved efficiency, consistent quality, customization options, and cost savings. By understanding the working principles, types, factors to consider when choosing a machine, and maintenance tips, manufacturers can make informed decisions and optimize their shade net production processes.